Ndarugu Student City

Ndarugu Student City

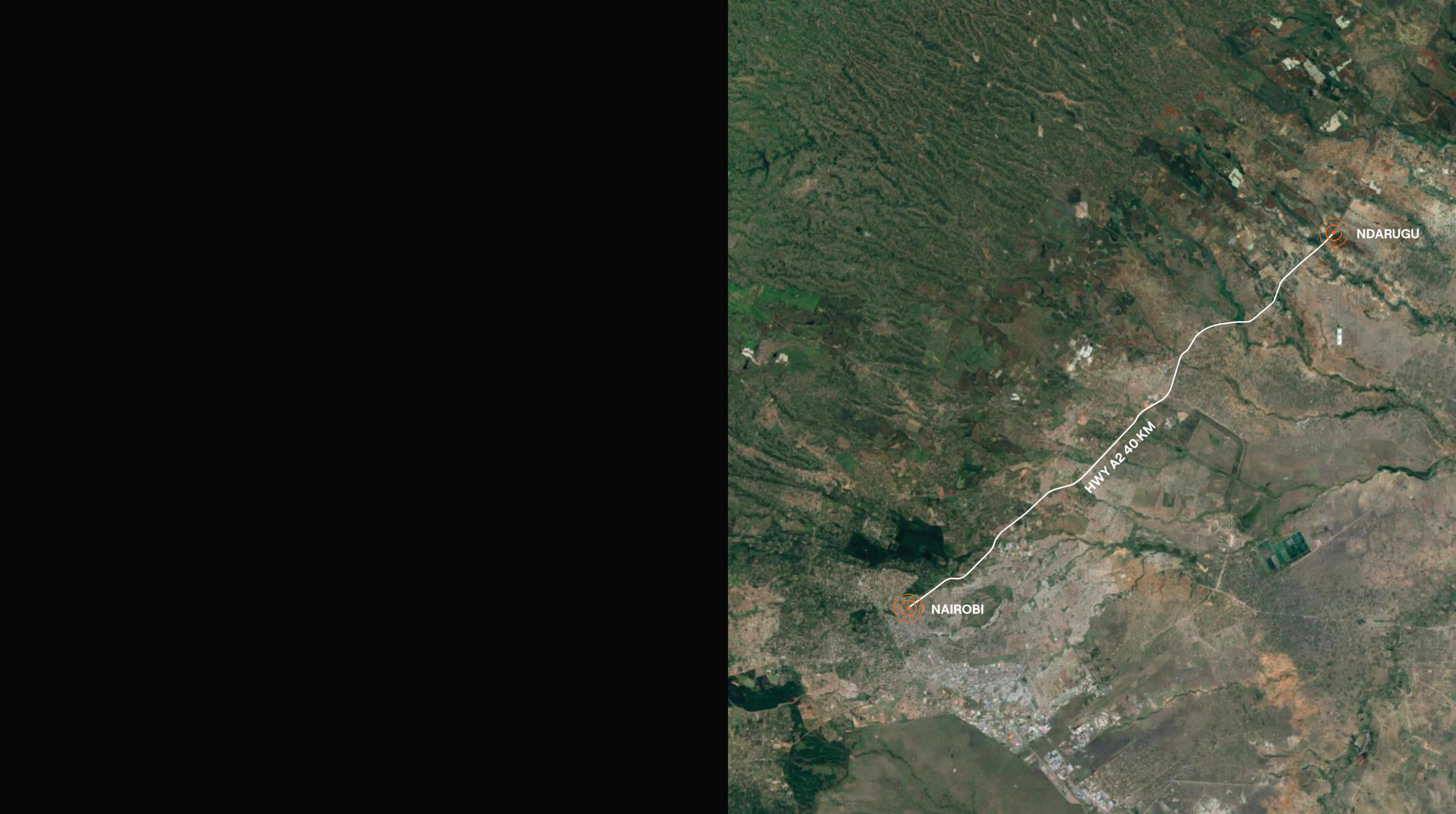

Location

Ndarugu, Kiambu County, Kenya

Client

Arvet & Ndarugu Metropolis

Status

Feasability study, 2018

Prototype, 2024

Program

Modular student housing in CLT

Size

1.6 ha, 34 000 m2 GFA, 880 apartments

Project team

Kayrokh Moattar

Frantisek Orth

Niels Pettersson Sandmark

Ivan Segato, Varg Arkitekter (protoype)

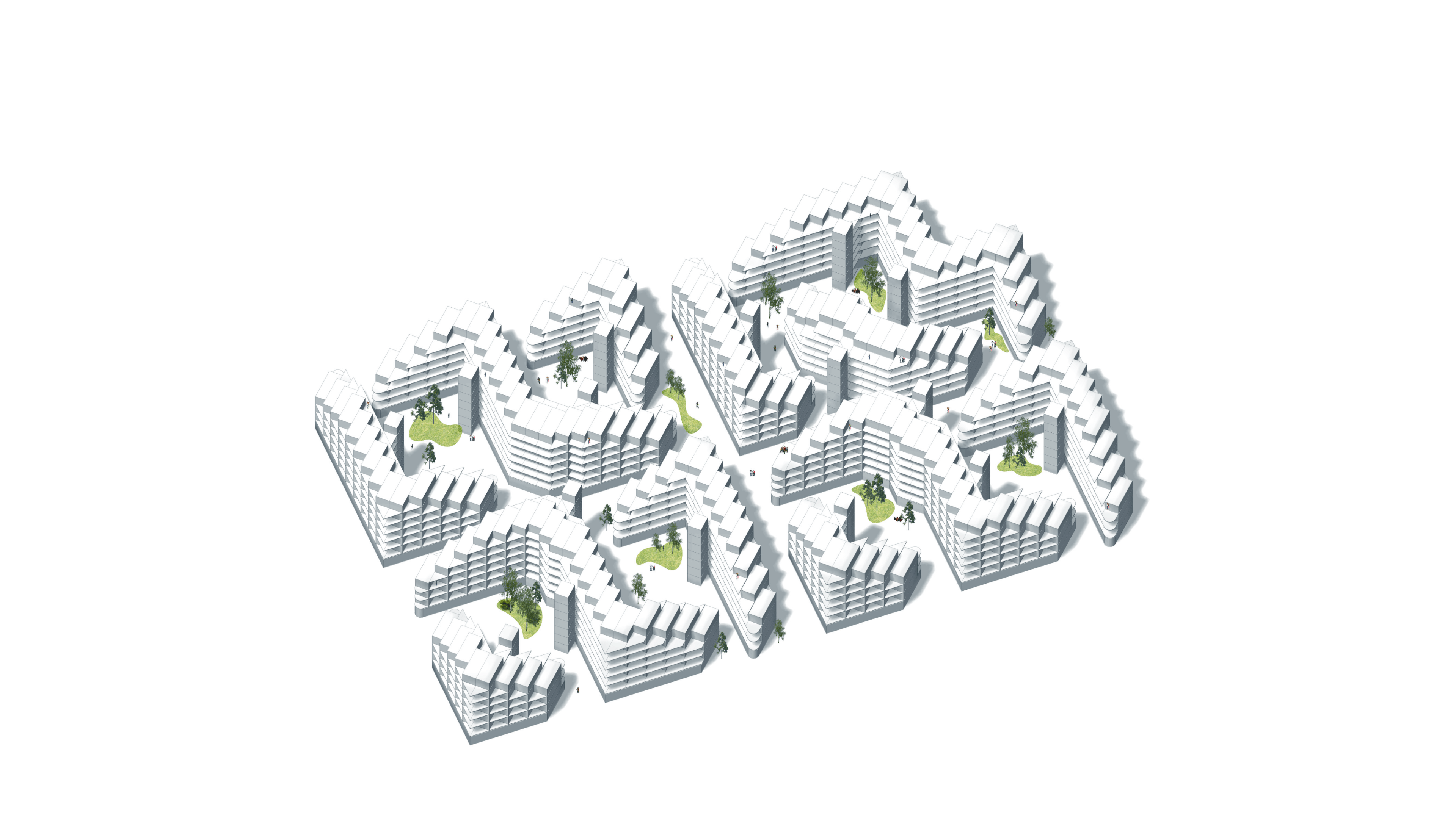

The project aims to explore how a modular CLT-system could be employed to imagine a relatively densely built and populated urban fabric with full opportunities for high qualitative public-, shared- and commercial spaces.

The test area, roughly comprised out of two parcels of land, 4 acres in total, divided by a road and is located in the south-eastern parts of the quarry. This is where we tested our ideas on modularity, stacking, blocking and density.

In 2024 our friend and colleague at Varg Arkitekter, Ivan Segato, traveled to Nairobi to supervise the construction of a prototype building made up of four of our CLT modules. We now look forward to the insights this experiment will bring.

Location

Ndarugu, Kiambu County, Kenya

Client

Arvet & Ndarugu Metropolis

Status

Feasability study, 2018

Prototype, 2024

Program

Modular student housing in CLT

Size

1.6 ha, 34 000 m2 GFA, 880 apartments

Project team

Kayrokh Moattar

Frantisek Orth

Niels Pettersson Sandmark

Ivan Segato, Varg Arktiekter (protoype)

The project aims to explore how a modular CLT-system could be employed to imagine a relatively densely built and populated urban fabric with full opportunities for high qualitative public-, shared- and commercial spaces.

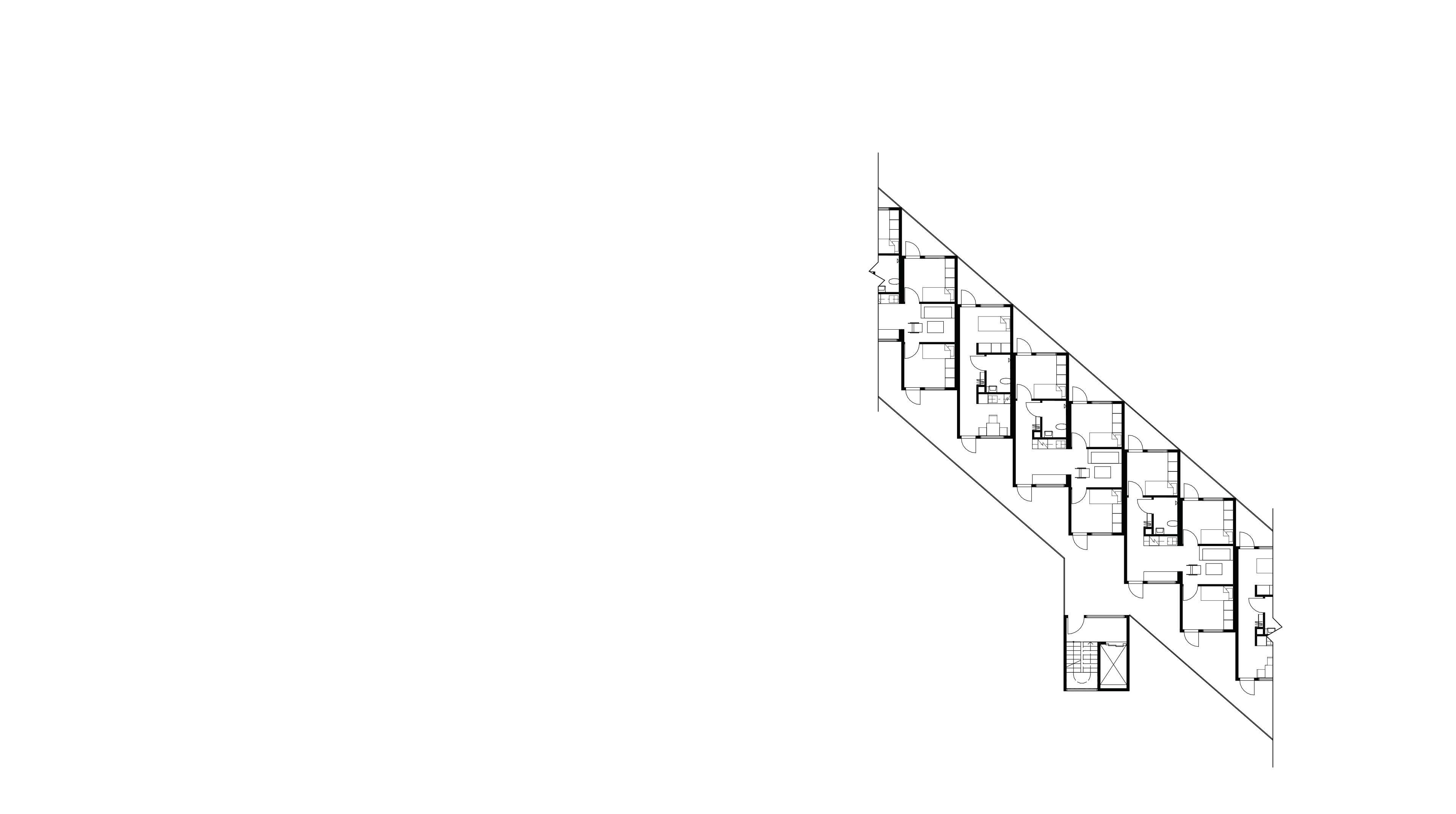

The test area, roughly comprised out of two parcels of land, 4 acres in total, divided by a road and is located in the south-eastern parts of the quarry. This is where we tested our ideas on modularity, stacking, blocking and density.

In 2024 our friend and colleague at Varg Arkitekter, Ivan Segato, traveled to Nairobi to supervise the construction of a prototype building made up of four of our CLT modules. We now look forward to the insights this experiment will bring.

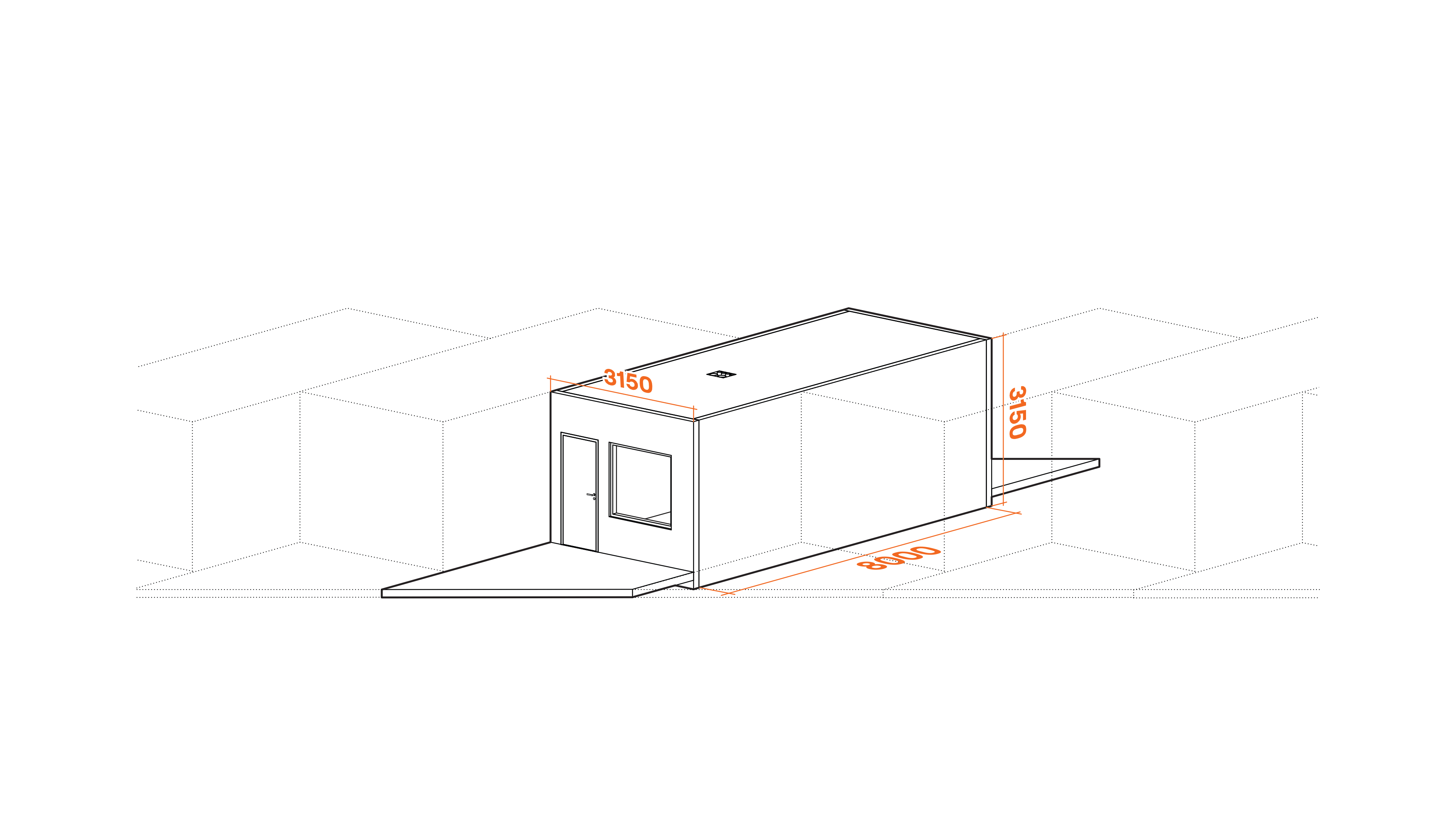

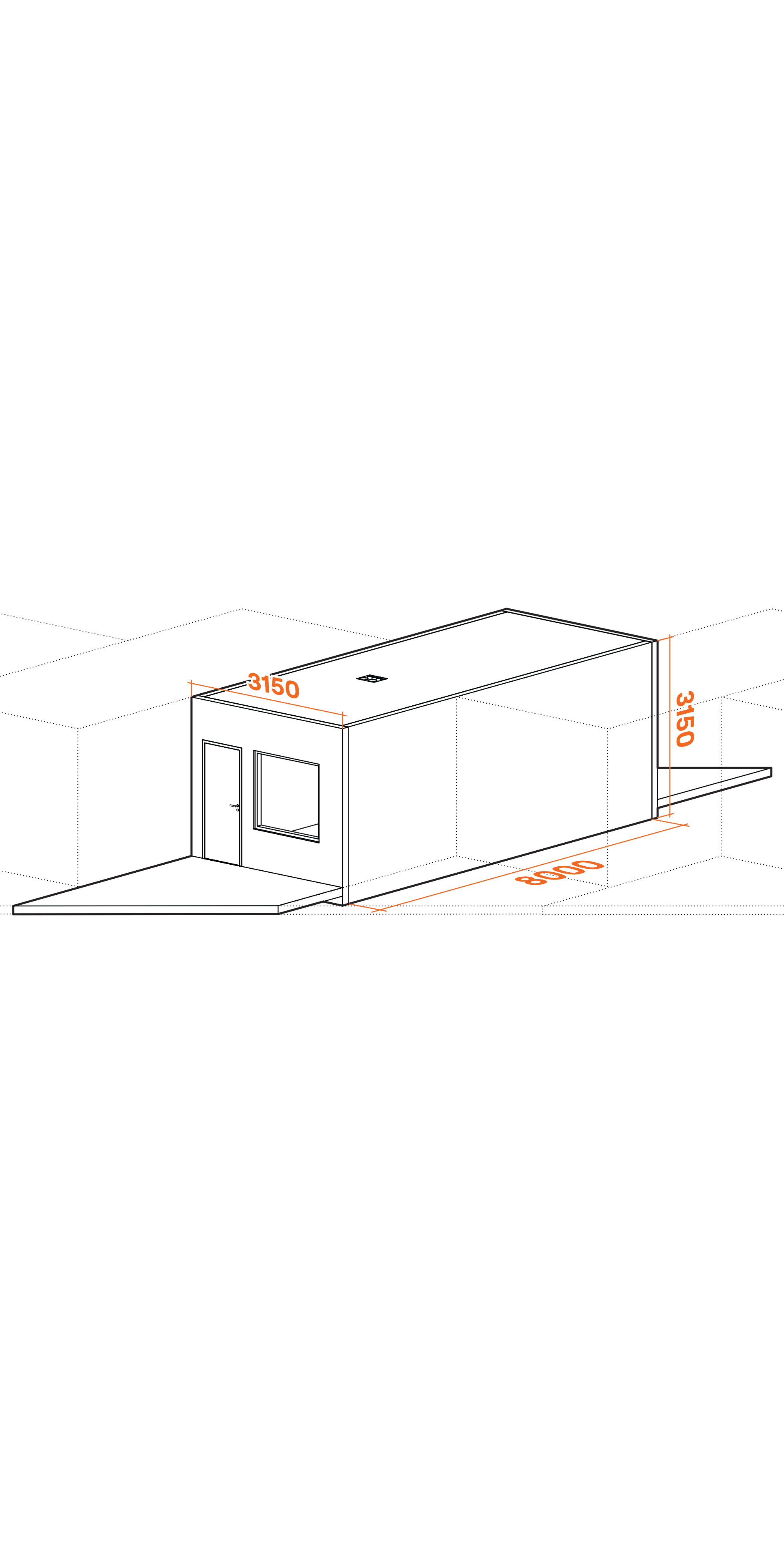

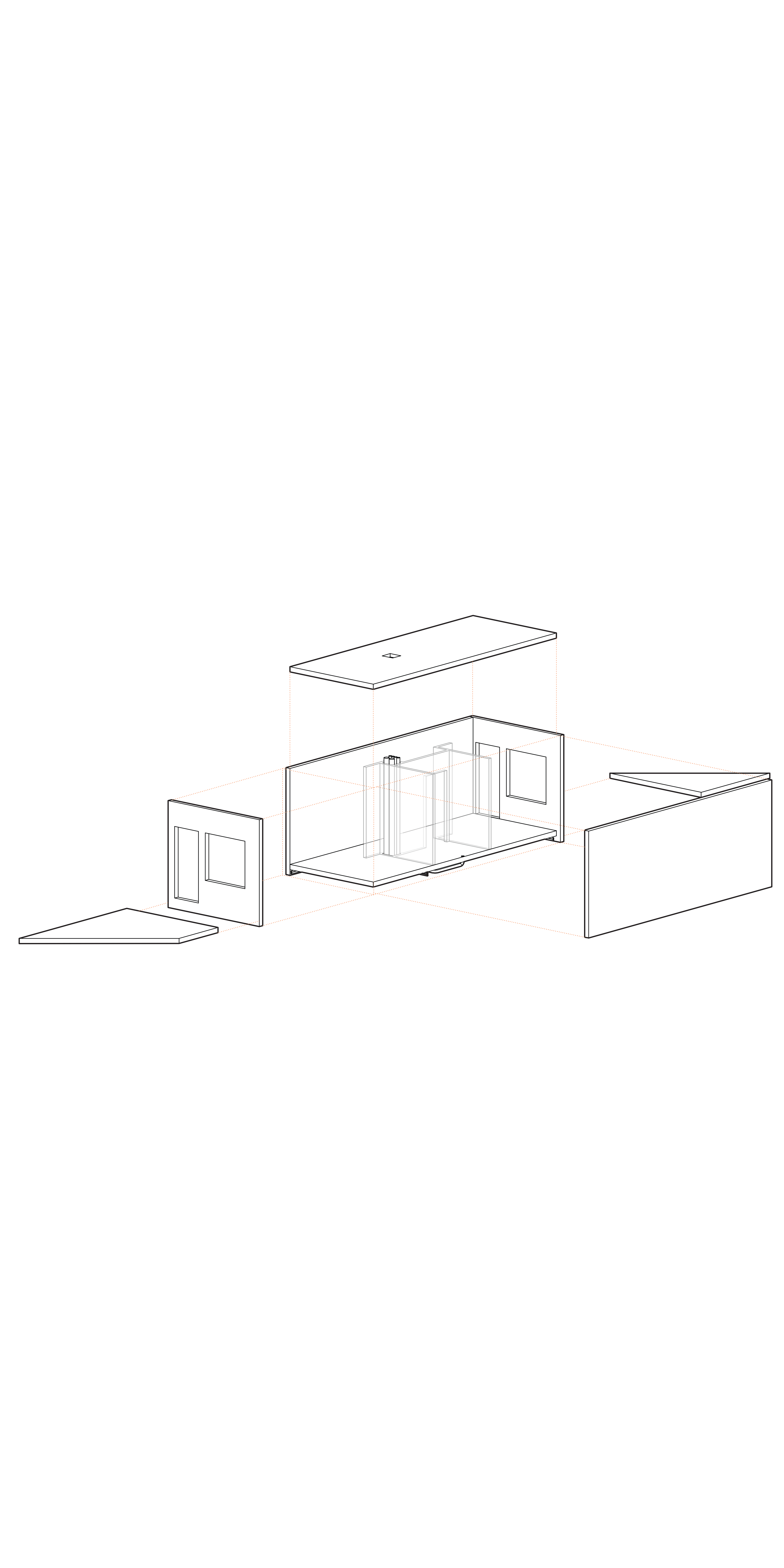

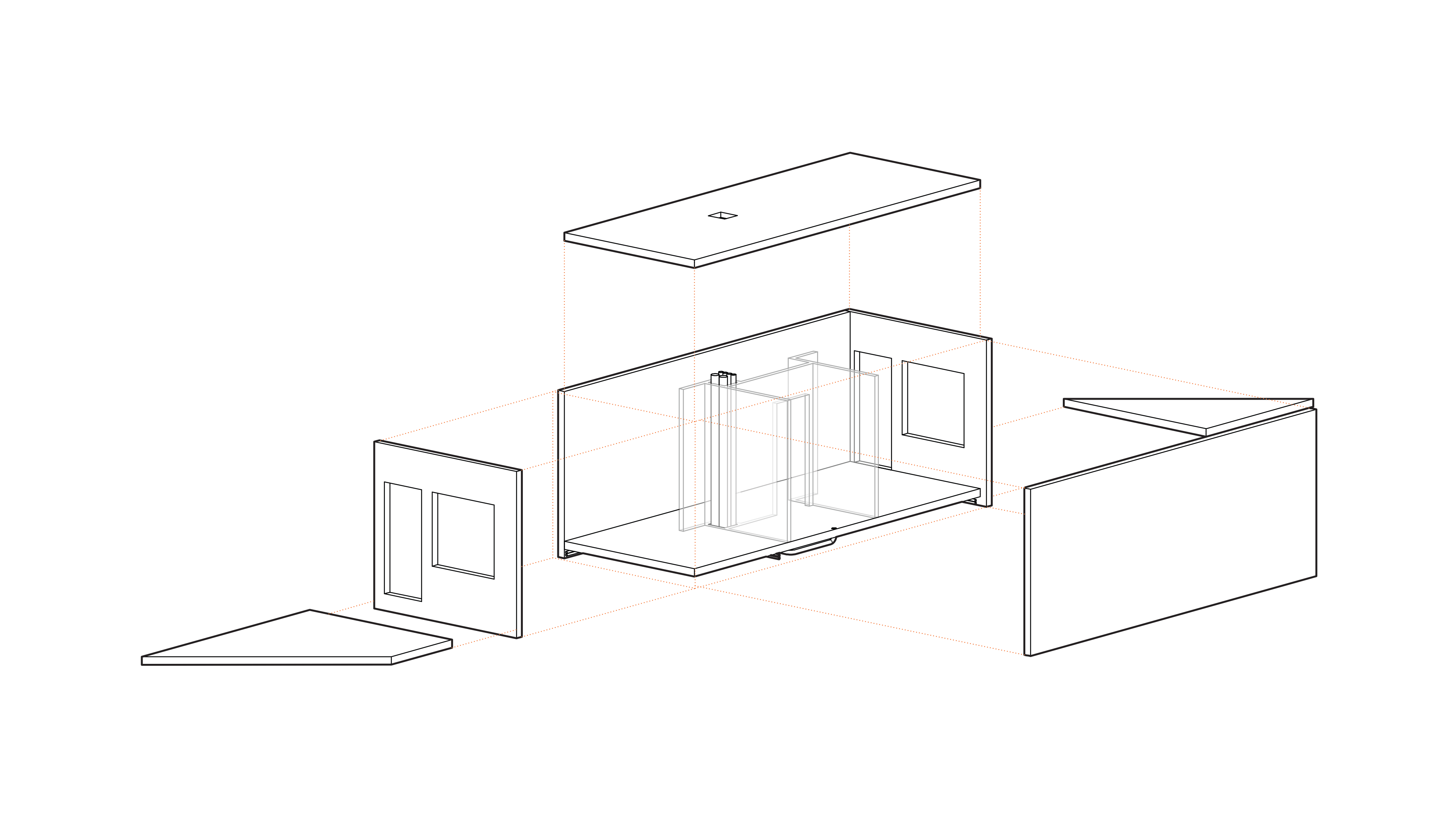

The Module

Principle

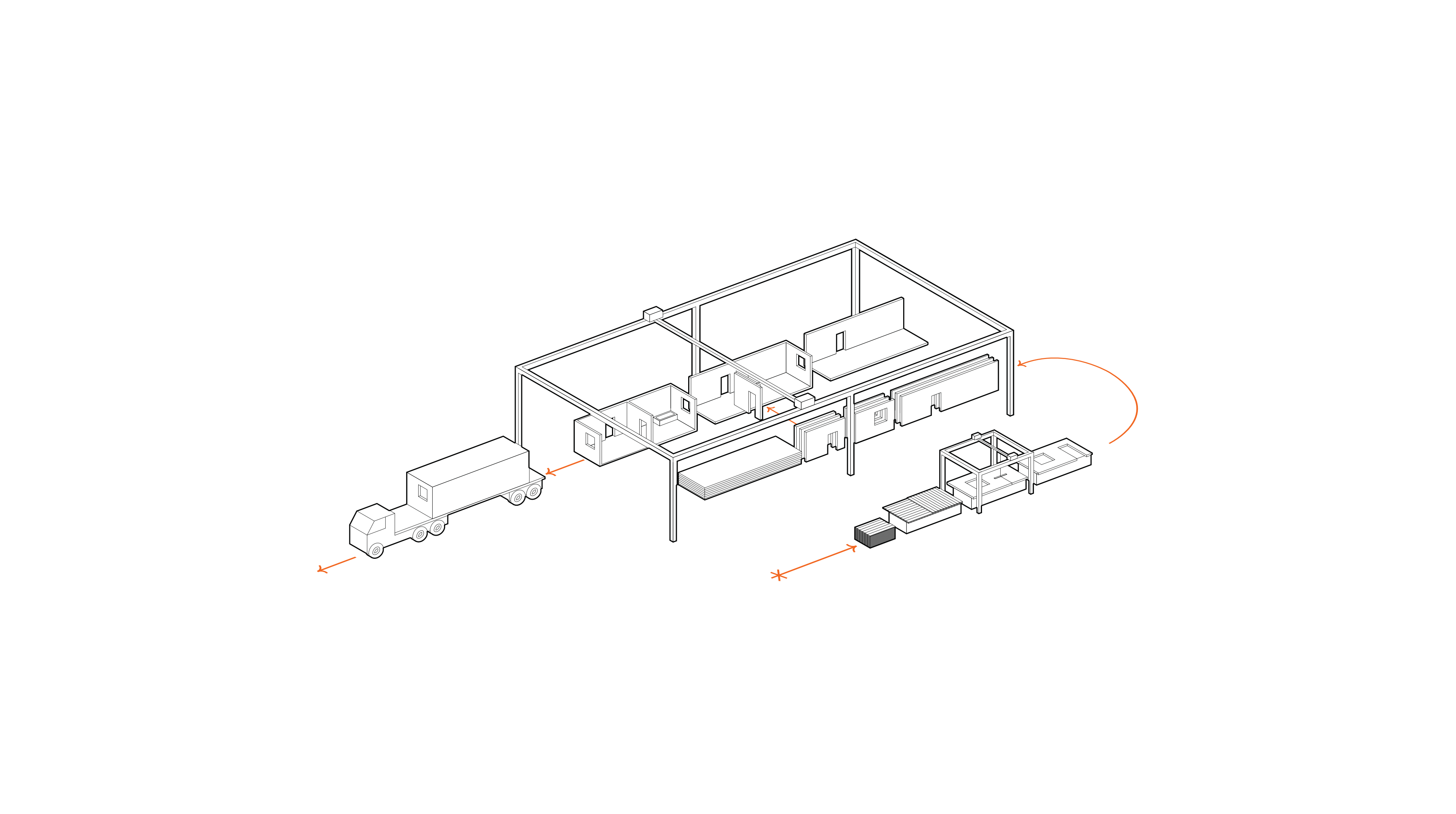

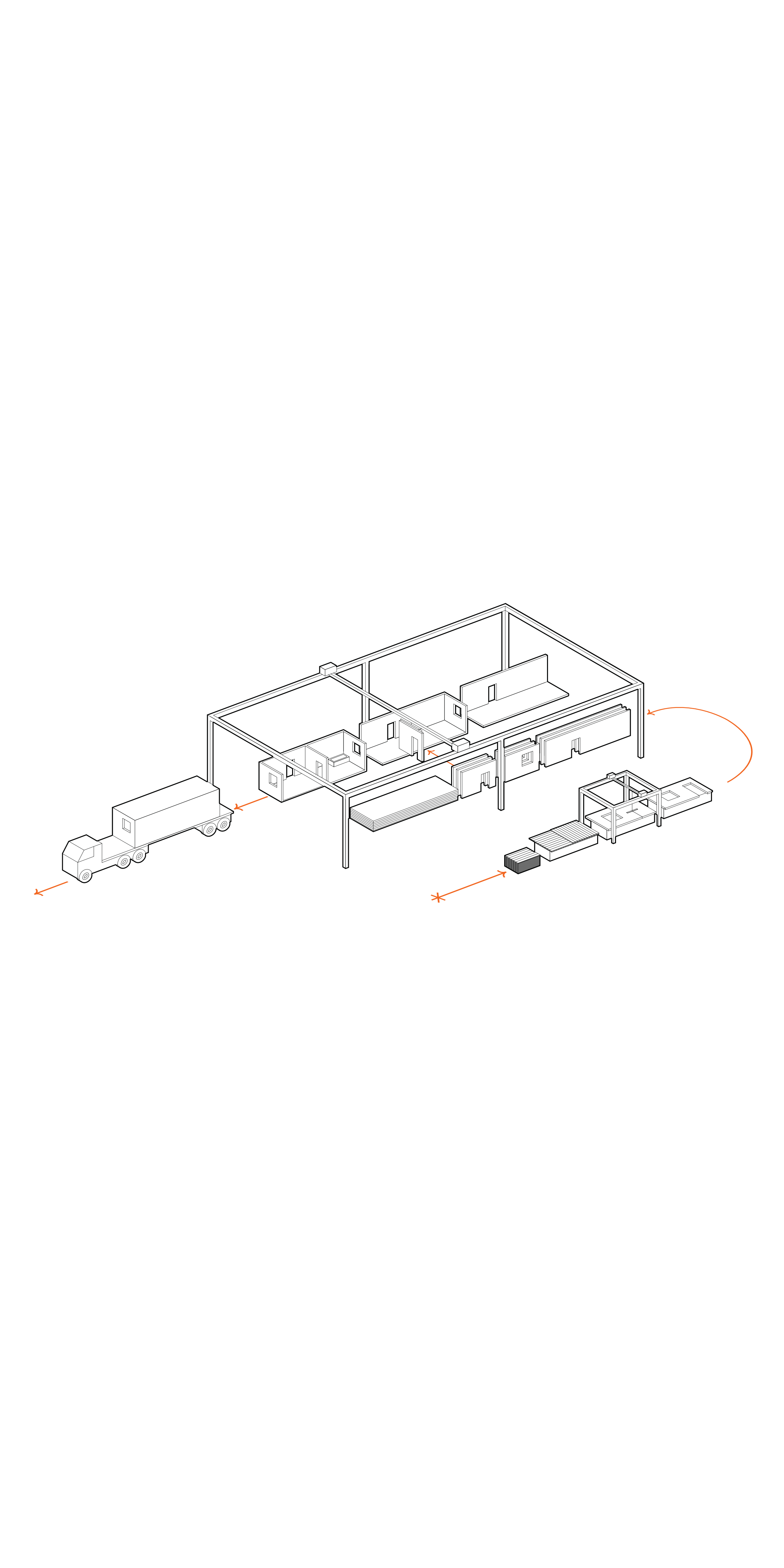

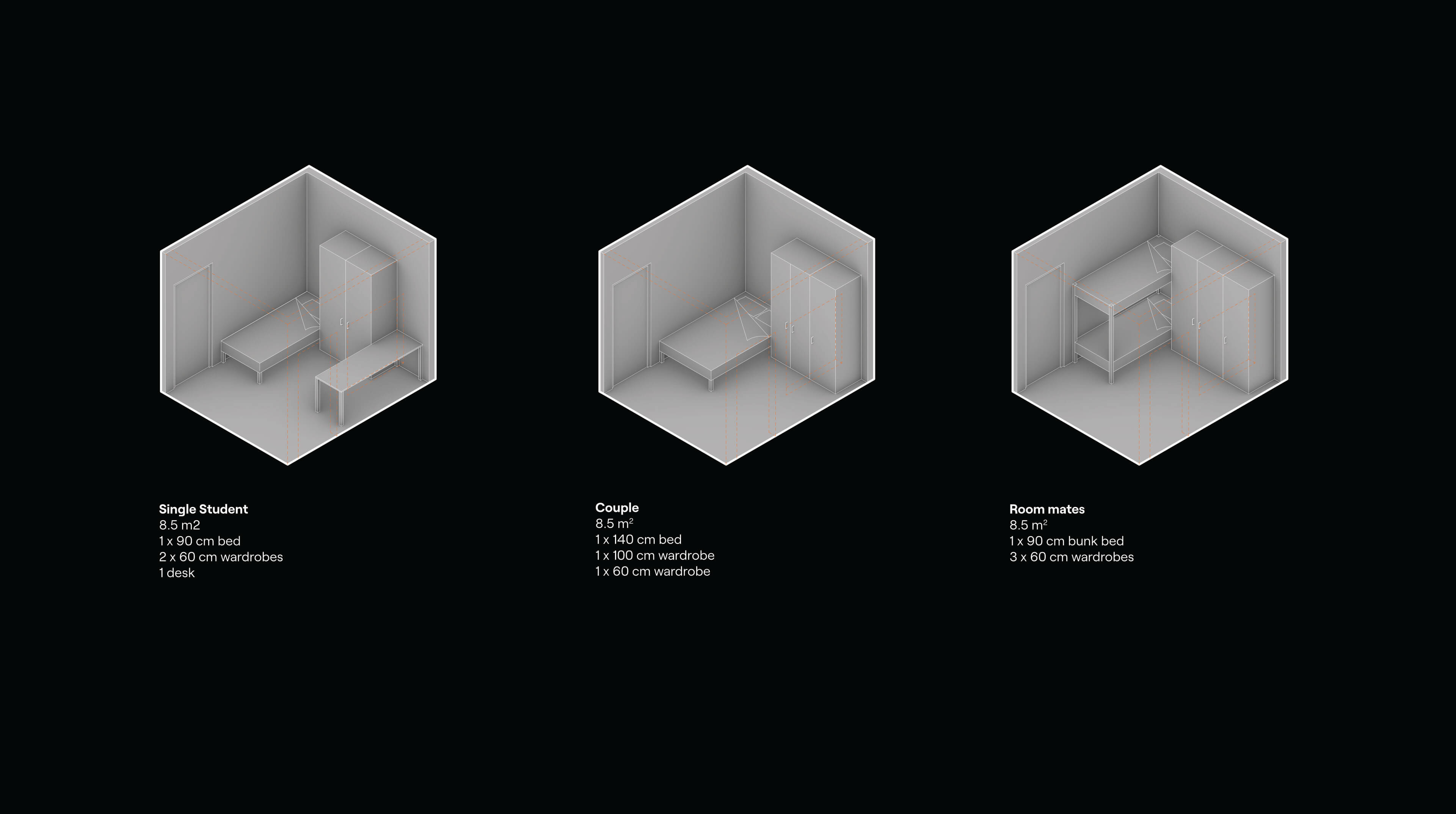

Modules are designed to minimize cut-offs and waste using the full width of the CLT panels. A MEP systems gap is placed under the floor to make factory assembly and transport of modules possible without damaging the MEP.

Production

CLT panels in full standard width are produced in a factory close to the site. Openings are made in the panels where doors and windows are to be placed. The modules are assembled in the factory, complete with MEP systems and joinery, and then transported to the site.

Problem

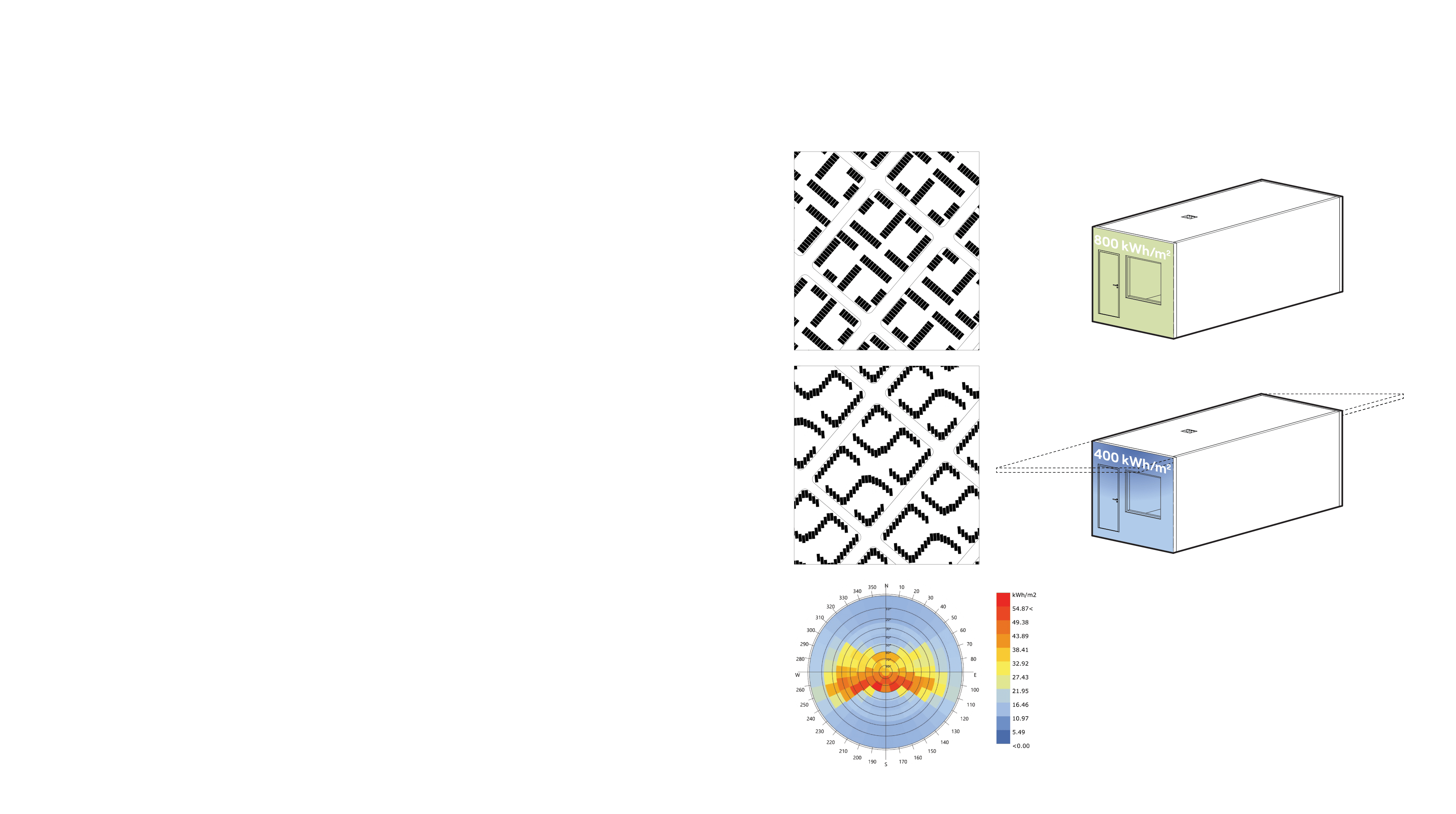

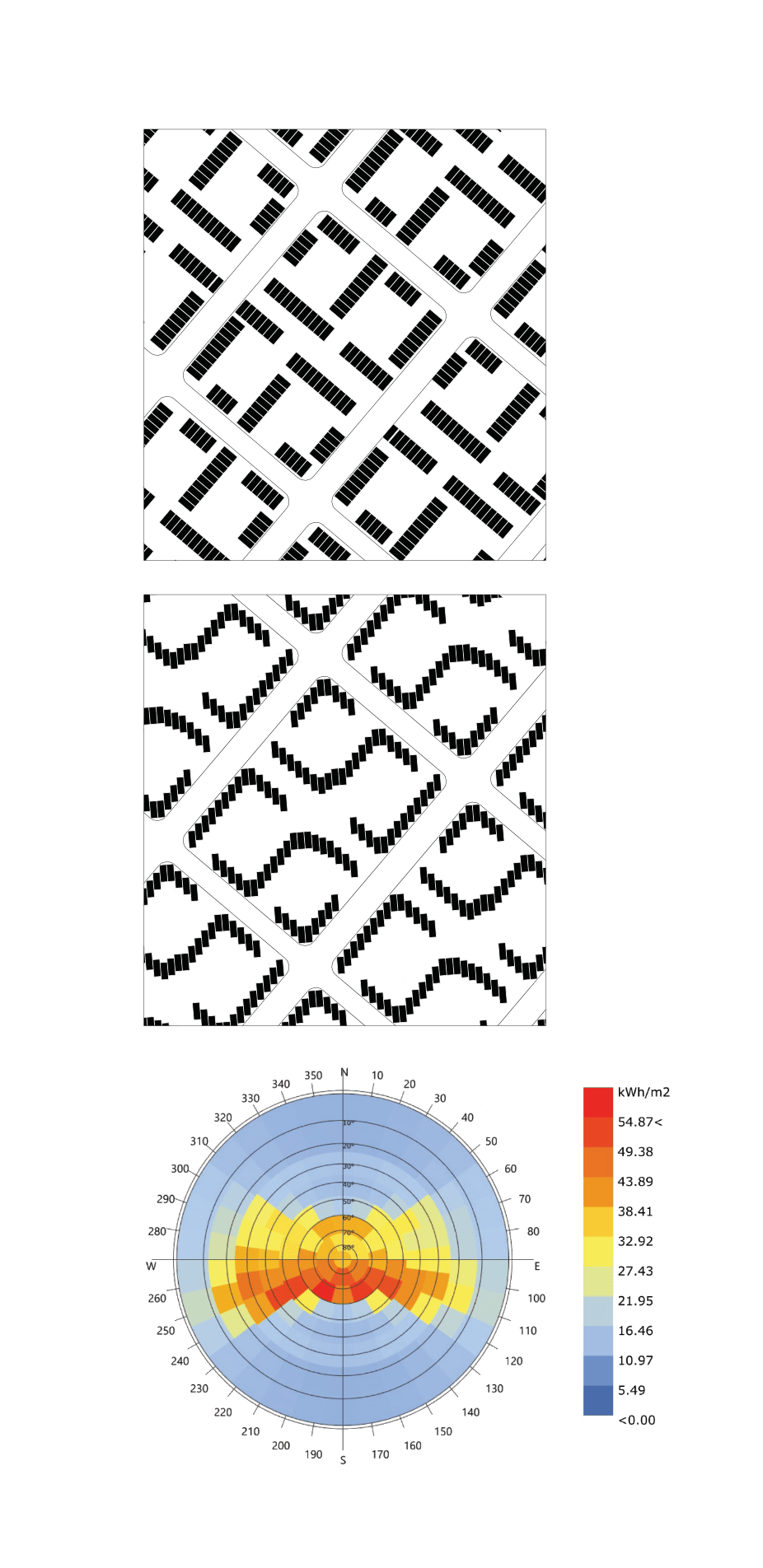

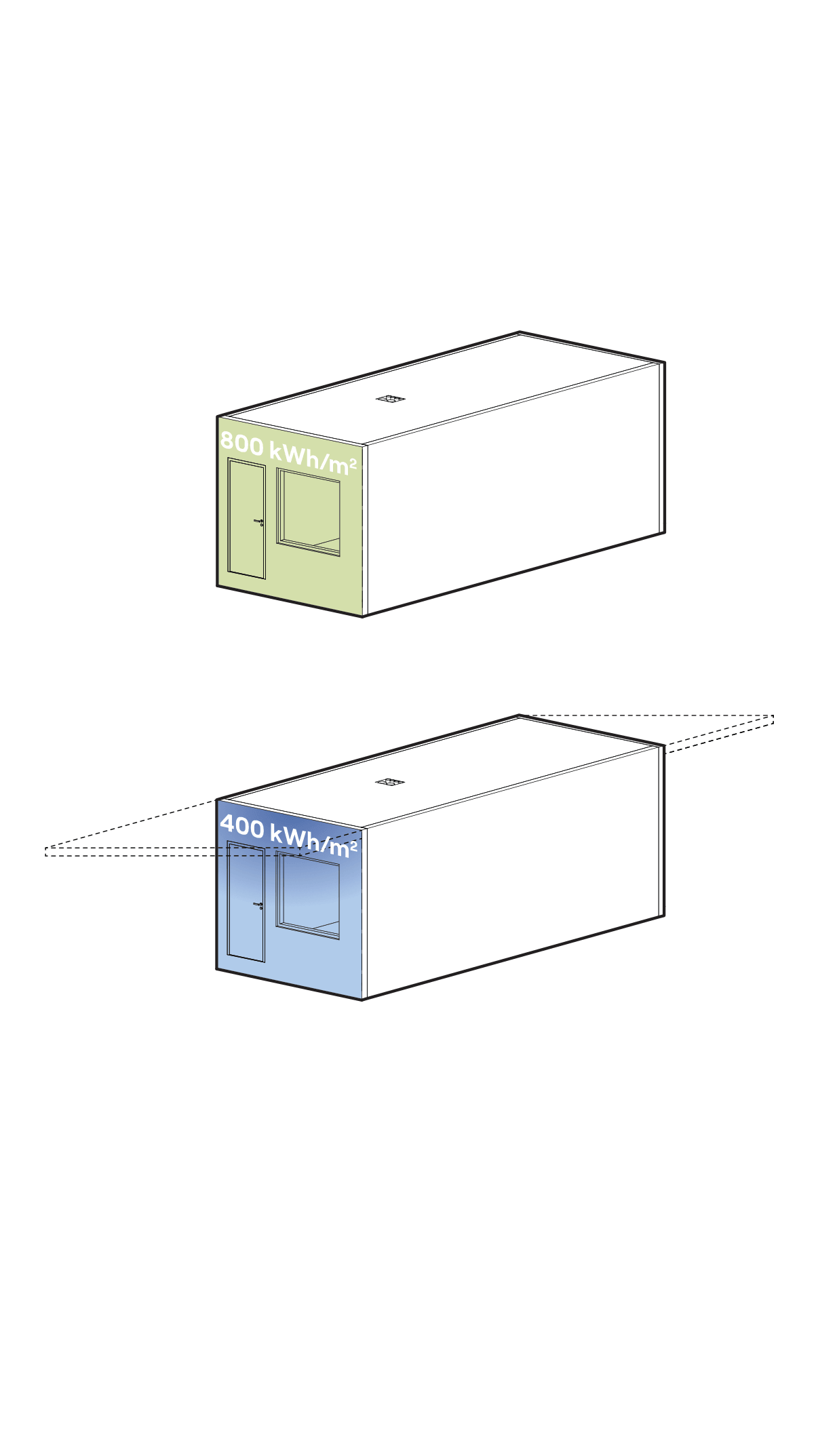

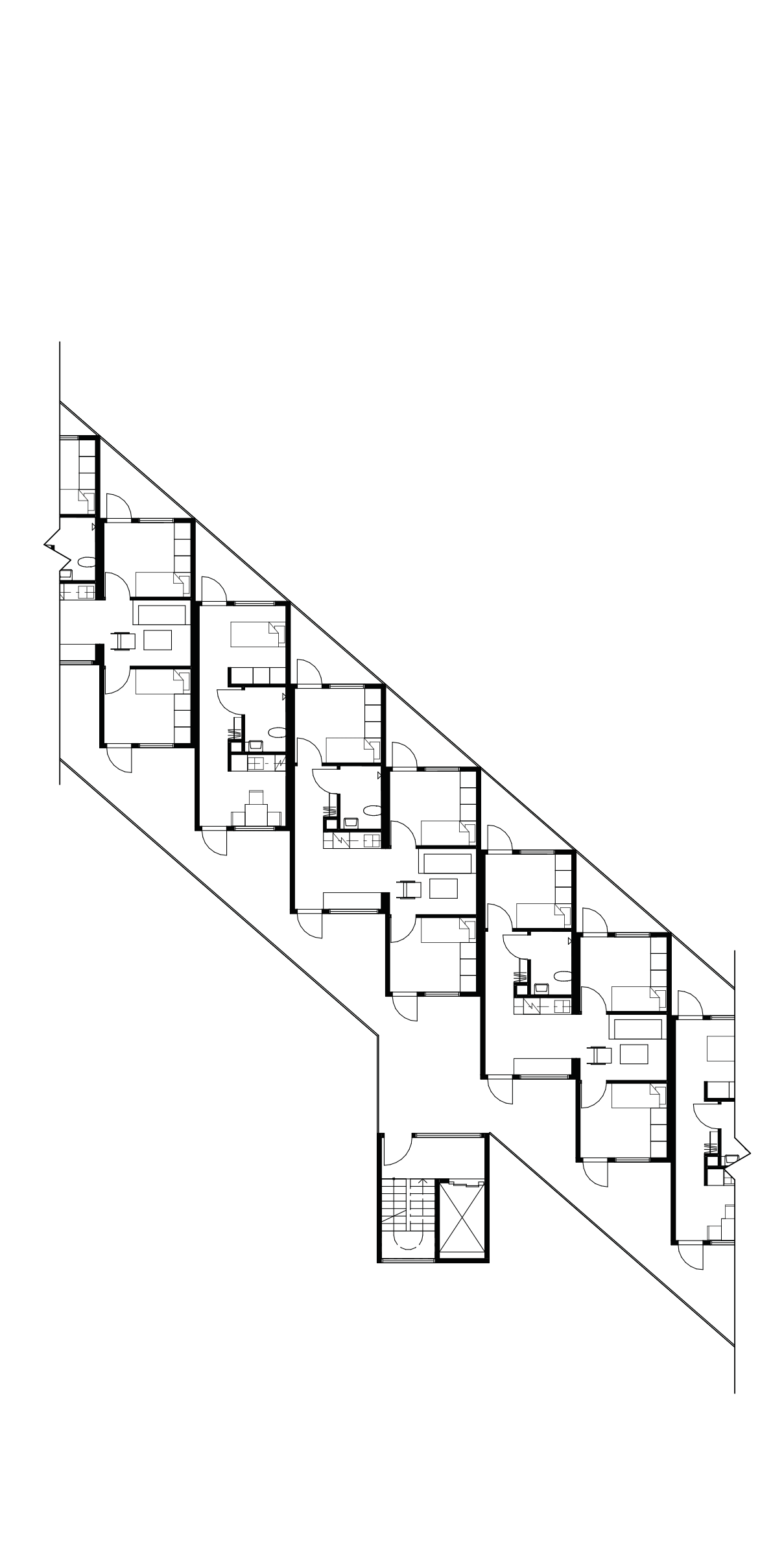

The street network and parceling in the master plan implies that individual apartments should have facades (short sides) facing NW/SE or NE/SW. According to weather data this gives high numbers of radiation on the faces that are most sensitive to solar heat gains, which in a hot climate is far from optimal.

Solution

By rotating the modules so that all short sides face N/S solar heat gains will drop. The effect is heightened by the addition of balconies and access balconies, shading the facades. This in combination with making all apartments two-sided, enabling natural ventilation, will result in a significantly higher potential to provide the students with a comfortable indoor climate.

The Module

Problem

The street network and parceling in the master plan implies that individual apartments should have facades (short sides) facing NW/SE or NE/SW. According to weather data this gives high numbers of radiation on the faces that are most sensitive to solar heat gains, which in a hot climate is far from optimal.

Solution

By rotating the modules so that all short sides face N/S solar heat gains will drop. The effect is heightened by the addition of balconies and access balconies, shading the facades. This in combination with making all apartments two-sided, enabling natural ventilation, will result in a significantly higher potential to provide the students with a comfortable indoor climate.

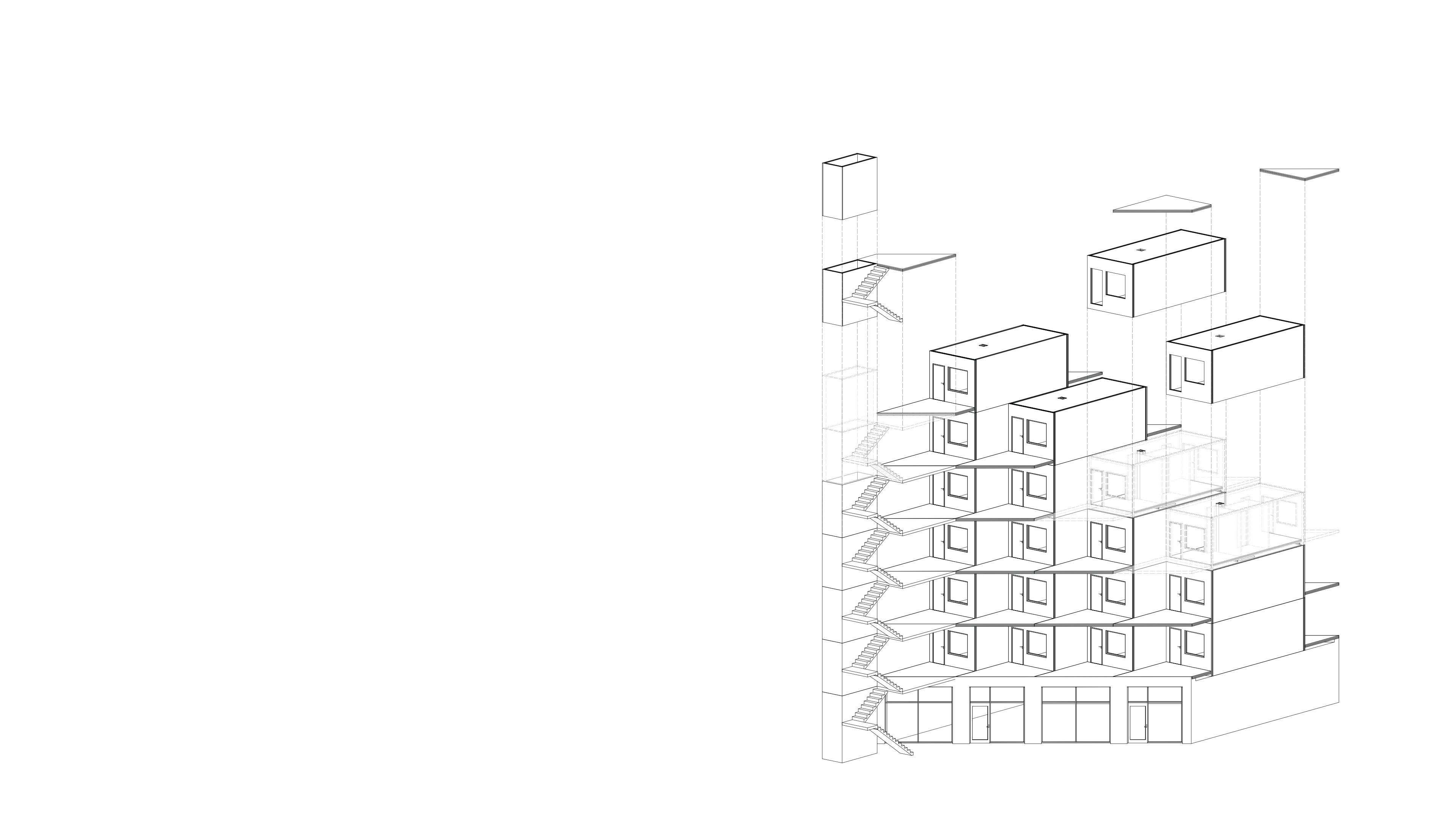

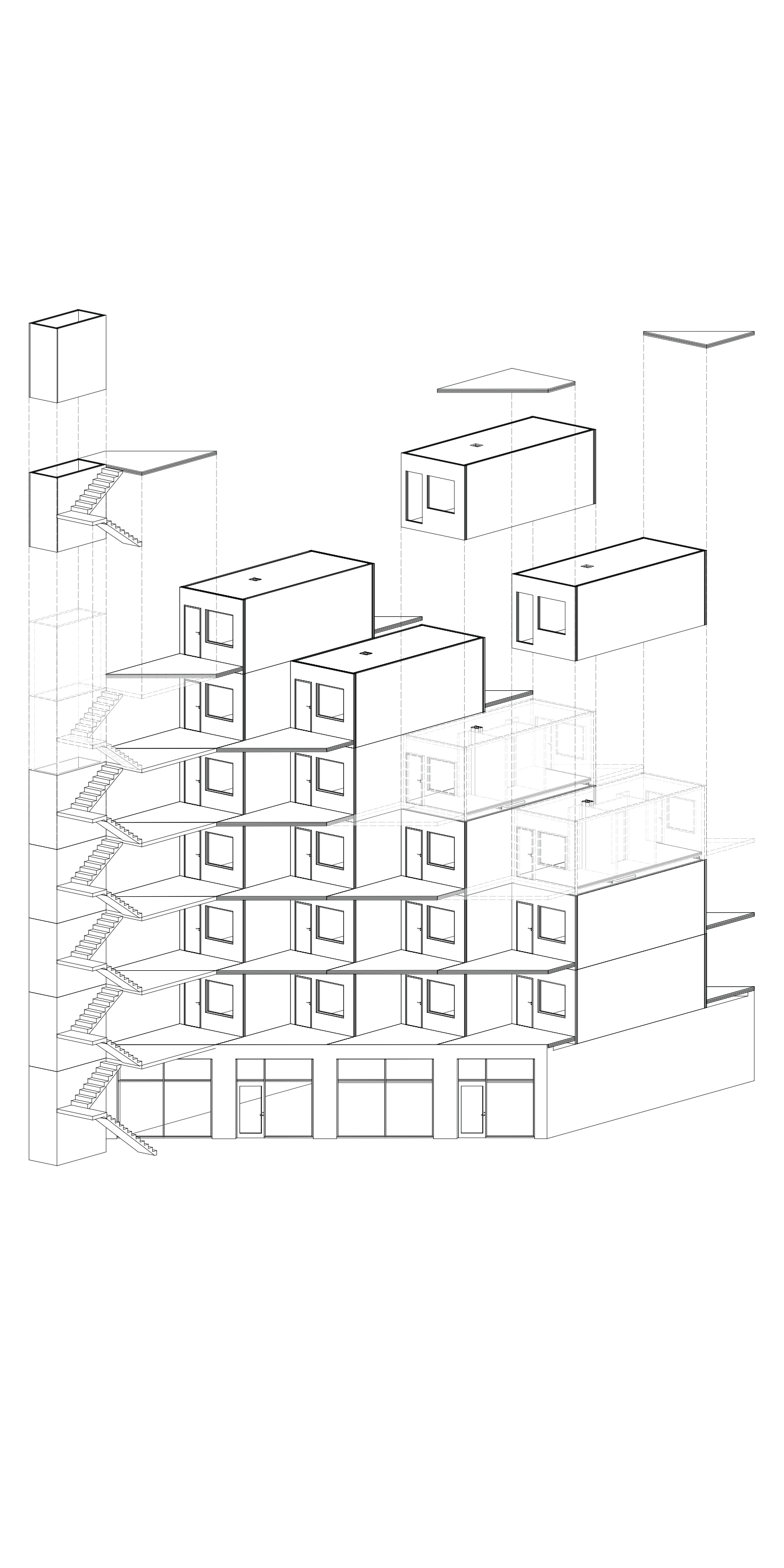

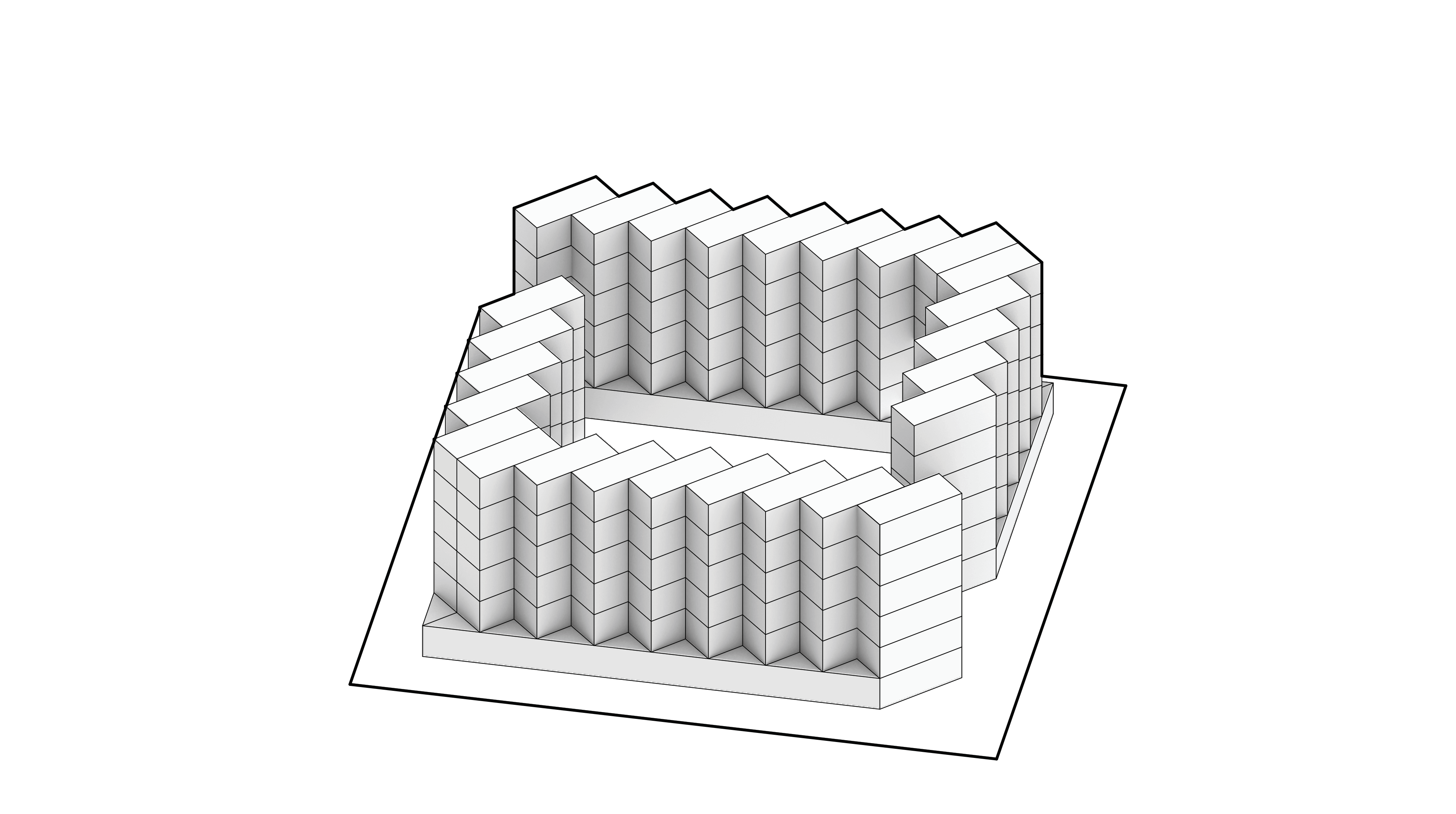

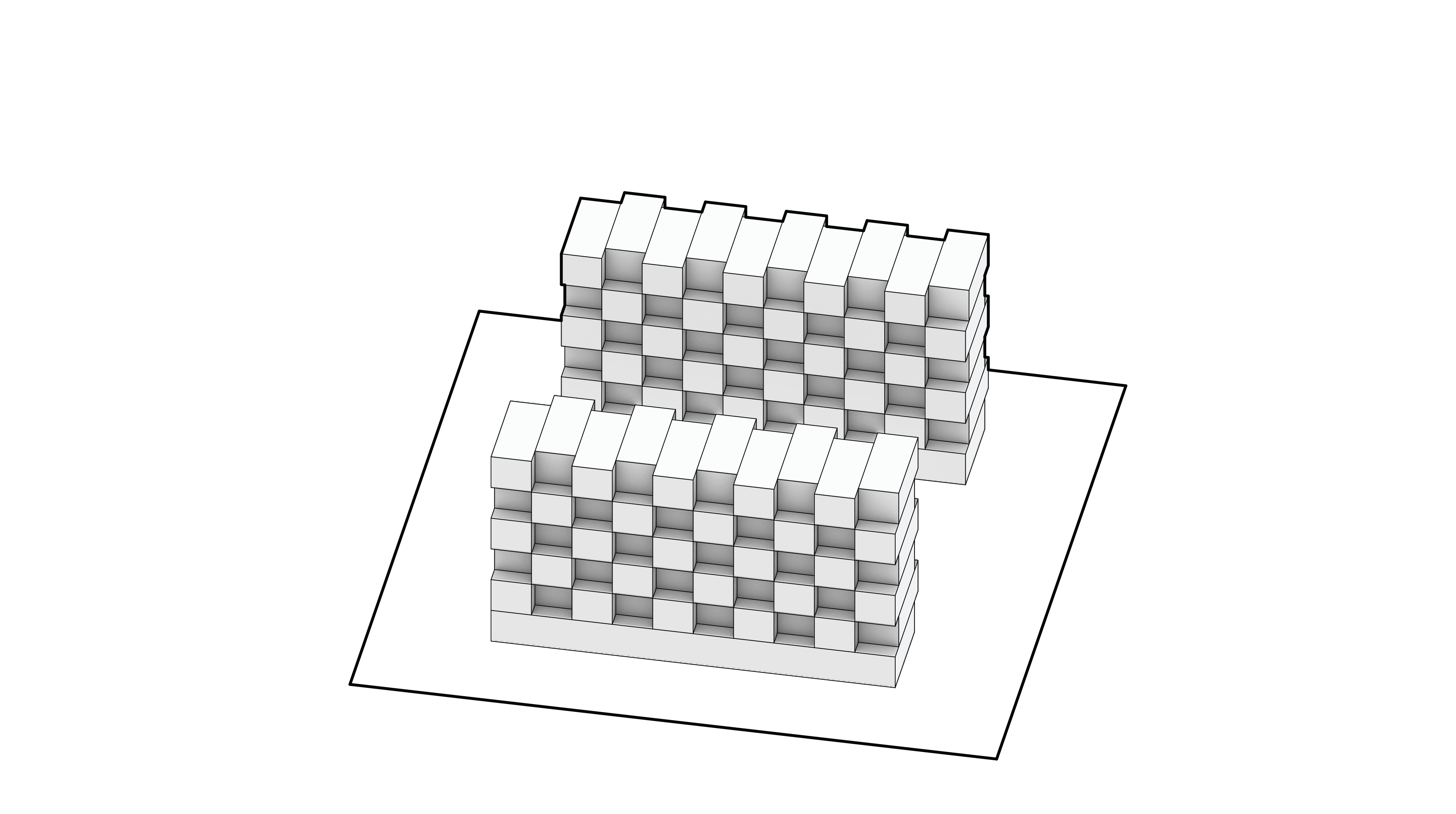

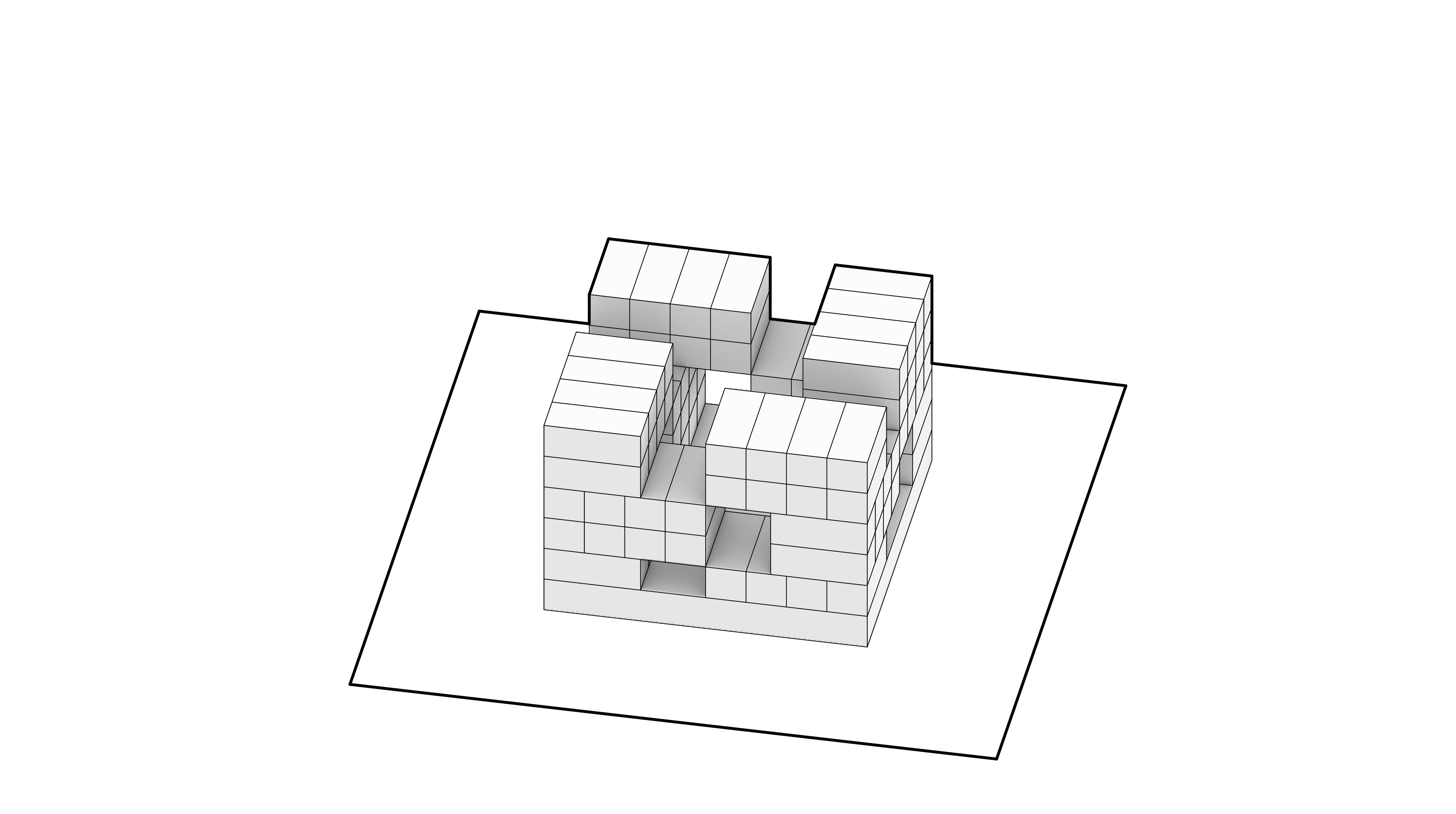

Stacking the Module

CLT housing modules are stacked on top of concrete ground floor structure, which contains shared spaces, shops, restaurants and complimentary services. Staircase and elevator towers come prefabricated from factory and the clever design of the modules requires minimal on-site MEP systems completion. The modules can be stacked in different ways depending on urban, climatic and natural context, allowing for a variation within the urban fabric.

Stacking the Module

CLT housing modules are stacked on top of concrete ground floor structure, which contains shared spaces, shops, restaurants and complimentary services. Staircase and elevator towers come prefabricated from factory and the clever design of the modules requires minimal on-site MEP systems completion. The modules can be stacked in different ways depending on urban, climatic and natural context, allowing for a variation within the urban fabric.

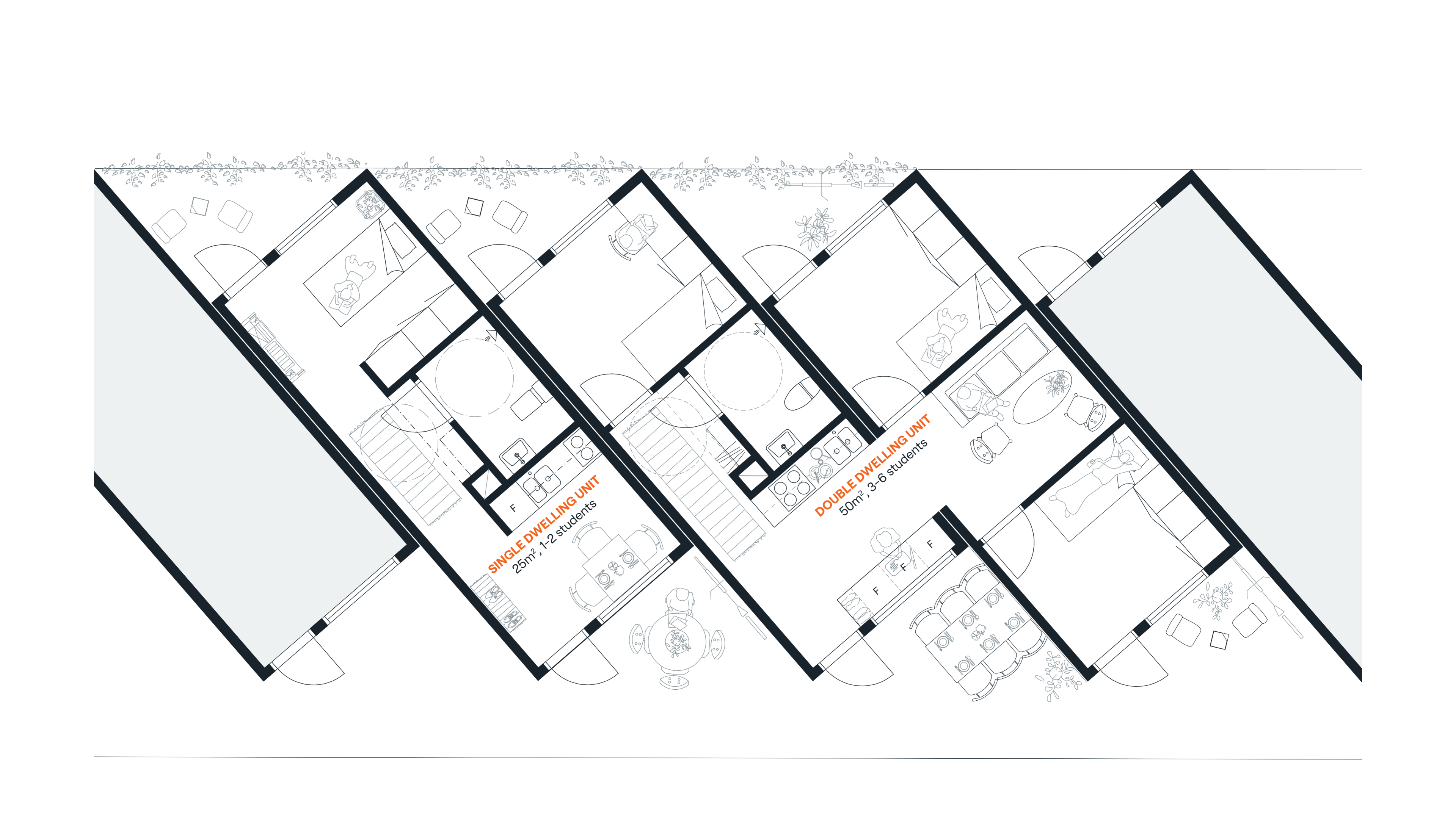

The Dwelling Unit

Modules can be combined into two different dwelling units: the Single Unit (25m2, 1-2 students) and the Double Unit (50 m2, 3-6 students). Both are designed according to the ”Easy Accessibility”-guidelines of UN Enable. In addition to private rooms, they include a kitchen, bathroom as well as interior and exterior social spaces.

The Dwelling Unit

Modules can be combined into two different dwelling units: the Single Unit (25m2, 1-2 students) and the Double Unit (50 m2, 3-6 students). Both are designed according to the ”Easy Accessibility”-guidelines of UN Enable. In addition to private rooms, they include a kitchen, bathroom as well as interior and exterior social spaces.

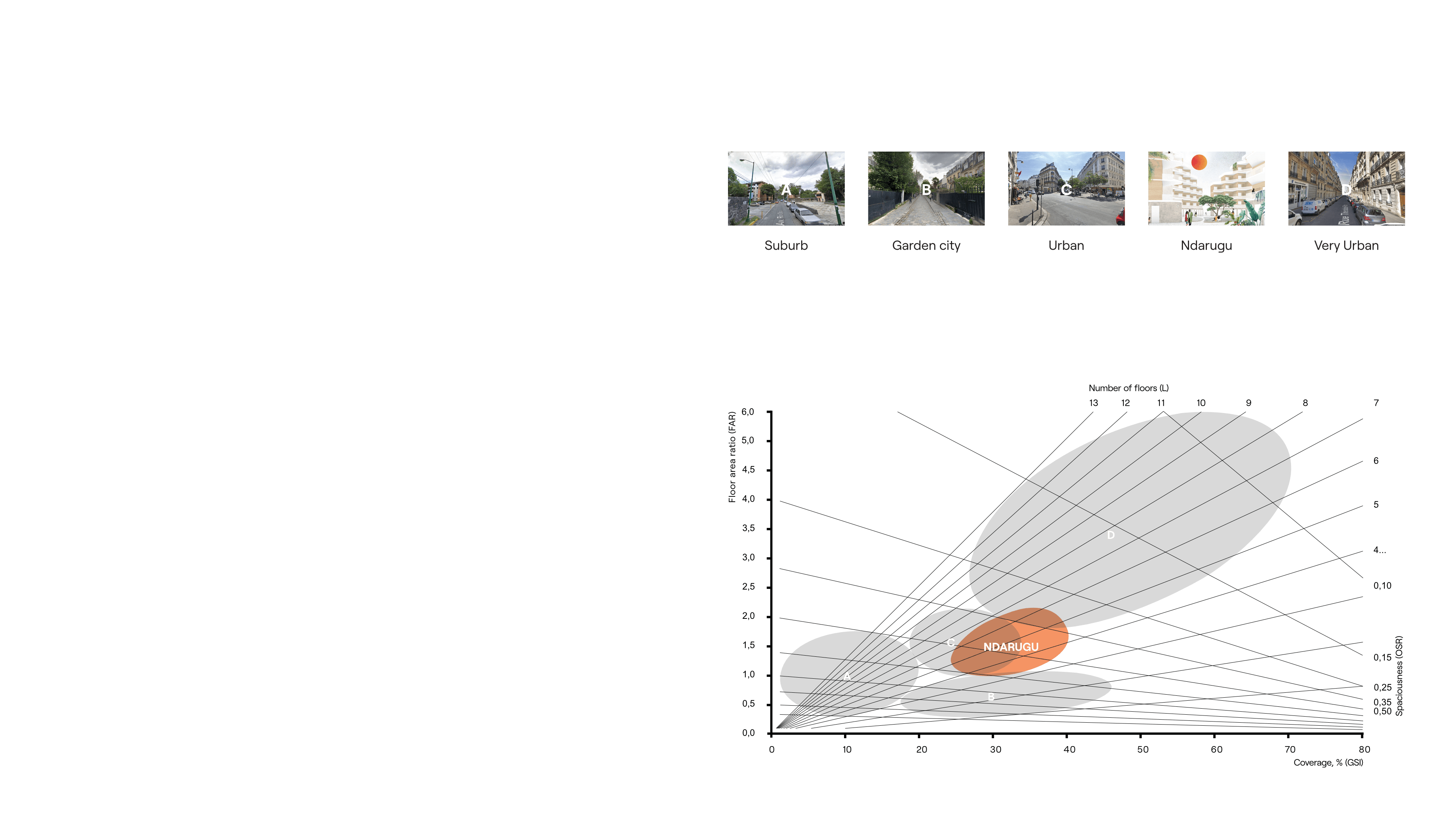

Density

Based on our pre-studies and earlier experiences of large-scale developments and with a goal of providing urban qualities, our hypothesis for the Ndarugu Student City is that it should have a FAR of about 1.5 - 2.2. But FAR is not the only figure to look at when it comes to density.

The Spacemate diagram links density, typologies of land development, urban environments, and non-built space in a single coherent measurement. In order to give opportunity for a dense yet qualitative urban neighbourhood our pre-studies show that the land of Ndarugu student city should be developed so that it corresponds to the orange area of the diagram:

• 3-7 floor developments (L)

• Covering approximately 35% of the total area (GSI)

• Floor area ratio ranging between 1,5-2,2 (FAR)

• 0,5 m2 of non built area for every 1 m2 of built area (OSR)